Find out what changes in the new CAMM2 RAM memory standard and how it can benefit both manufacturers and consumers

The new memories RAM The CAMM2 standard was one of the Computex 2024 Highlights, attracting attention for its different format and specifications. Various companies presented products already with new memoriesand the Kingston reserved a good part of its stand to show what changes in the new format and how this positively affects producers and consumers.

- How to find out the size, type and frequency of your PC’s RAM memory?

- What is DDR (Double Data Rate) memory?

The initial strong point is the possibility that new memories replace the LPDDR modules soldered to the motherboards. With this it will be possible perform memory upgrades on systems where, until now, this was not an option.

Furthermore, the technical project also brings with it a series of changes to improve performance on various fronts, instead of simply hosting more NAND chips, given that the new format limits this possibility.

How are the new CAMM2 RAM memories?

We current DDR standardsthe pinout is at the “edge” of the PCB, with the chips, microcontrollers, and other components distributed along one or both sides of the board, depending on the design, requiring the motherboard connector to be, to some extent, vertical .

To the specific case of notebooks, the solution to take up less space is to use swivel connectors, which fix the memory sticks at a very angle, almost lying down. However, this limits some more compact designs, such as ultra-thin and portable consoles.

Slimmer physical design

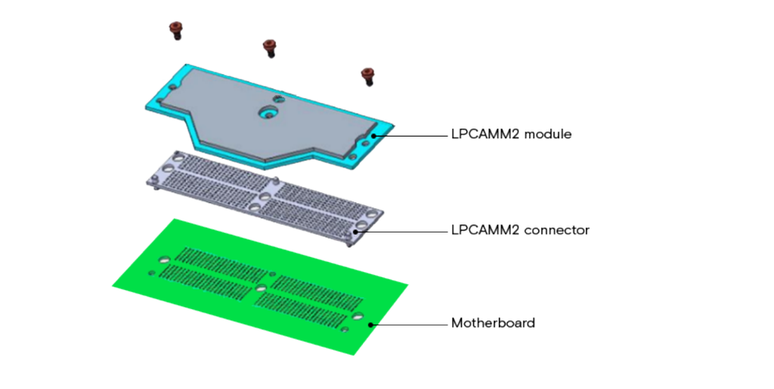

The first notable change in new CAMM2 memories Depending, obviously, on the arrangement and shape of the connectors, no longer on the edge, but on the bottom of the PCB. As a result, the fitting stops being vertical and becomes horizontal and flat, with smooth metal contacts, in an extremely slimmer design.

Choosing smooth contacts instead of the pins themselves prevents the memories or the motherboard connector from suffering deformations resulting from shocks, small vibrations during transport or during the installation of the components themselves.

The modules are fixed to the motherboard using 5 cross-head screws (Philips) with small “cradles” in the perforation, similar to those of the M.2 SSD. In this way, even ultra-thin and portable consoles can do without modules soldered to the motherboard, ensuring the possibility of updates in an ultra-compact format.

More efficient communication with the CPU

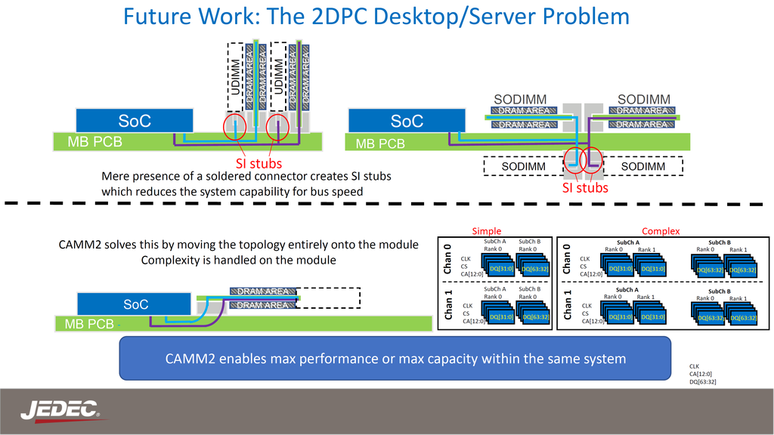

Of course, the small size alone would not justify the investment in a completely different memory standard. Traditional DDR standards benefit greatly from scalability because they are easily replaceable, but they depend on microcontrollers and other components that intermediate communication with the processor to be viable.

This distance and larger steps come forward CPU access to memory limits the speed at which instructions can be executed and, consequently, the performance of the system. These access times are what we call latency in memory specs, and stressing transfer speeds by overclocking memory improves top speed but hurts access times.

At the same time, LPDDR memories, soldered to motherboards, have more direct communication paths with processors, offering much lower latencies. More than the small profile, this is one of the main reasons why many manufacturers opt for LPDDR memories in their designs.

The new CAMM2 memory standard significantly reduces the distance between the memories and the processor, and increases the communication surface with the new connectors. This way, they provide much shorter access times and support higher transfer speeds, even without overclocking, all without compromising upgradeability.

Integrated dual channel

Another important difference is that modern systems use parallelism to increase computational efficiency and, for this reason, working with memory channels is also very important. The problem is that in current standards each channel requires a dedicated connector, with different distances for each channel, independent controllers, and all this directly affects access times.

In the new CAMM2 standard, the two memory channels are integrated into the same connector closer to the CPU and with a single controller. This significantly optimizes access times, but also makes the project easier for the manufacturers themselves.

By working with a single connector with two integrated memory channels, you can streamline the connector and memory validation process. This is because it is no longer necessary to validate each connector independently and then validate the entire set to determine memory speed and latency depending on whether the arrangement has one, two, or four sticks.

Positive and negative points of CAMM2

Like everything new technology, the initial production cost also ends up being higher, and this inevitably has repercussions on the final consumer. OR Canaltech was at Computex 2024 and motherboard manufacturers have suggested that the idea is for CAMM2 modules to follow a price range close to that practiced in the DDR standard, but some increase, however small, is inevitable.

If the technology catches on, research and production costs will eventually dilute over the years, but, at least initially, CAMM2 memories should be relatively more expensive than DDR5 sticks.

Strengths

- The horizontal profile allows you to replace soldered LPDDR memories

- Modularity for easy upgrade

- Proximity to the CPU reduces latencies

- The single connector facilitates development and validation

Negative points

- More expensive to produce

- Lower maximum memory density

- Scalability limited by motherboard size

- Installation is more delicate and uses screws

DDR combs allow you to use both sides of the PCB to accommodate chips and other components when needed. So much so that Micron has already confirmed that it is working with combined technologies that will soon make memories livable Scalable up to 1TB per memory stick.

However, depending on how these technologies are implemented, this level of scalability would no longer be achievable on notebooks or even desktops. Therefore, improving performance by targeting elements other than the density of NAND chips is a more attractive solution.

Look at @kingstontech the new CAMM2 RAM module. Is cute! #MSIxComputex2024 https://t.co/1sBY2GVz6A pic.twitter.com/JUcZFcH9ex

— MSI Gaming (@msigaming) June 7, 2024

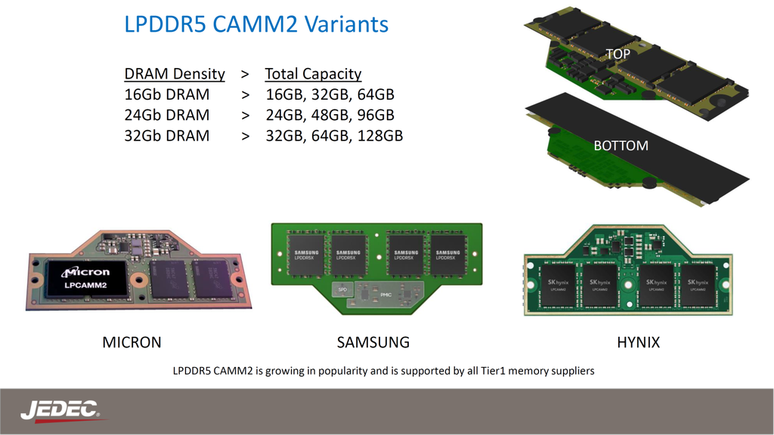

In the case of CAMM2 memories, a larger portion of the bottom side of the PCB is used to accommodate some controllers and the flat connector, reducing the total area available for the NAND chips. Initially, the density of the first models appears to be higher, with a single module reaching 128 GB.

On the other hand, long-term scalability simply expands the surface area of the entire comb, compromising a larger area of the devices’ motherboard, and posing a potential medium-term problem.

When will the CAMM2 memories be released?

According to what was stated by Canaltech managed to probe at Computex, the first memories should arrive on the market in the third quarter of 2024, with 32 GB, 64 GB and 128 GB modules. Initially, only ADATA, which is also a memory manufacturer, has already confirmed a portable console with the new CAMM2 standard.

In the notebook industry, the Lenovo has already launched the first ThinkPad P1 Gen 7 with replaceable CAMM2 memories, but there is no date yet for the model’s arrival in Brazil. On the desktop side, some motherboard manufacturers have brought CAMM2 boards to Computex for new processors Intel Arrow Lake, but without providing more in-depth technical details.

The price range, however, has not yet been revealed, but it is important to remember that The manufacturing cost of NAND chips has undergone several sequential adjustmentsmaking various products more expensive, from microSD cards to memories and SSDs.

- 🛒 Buy gaming notebook with 32 GB of RAM at the best price!

- 🛒 Buy RAM memory for desktops and notebooks at the best price!

Trends on Canaltech:

- Anderson Silva x Chael Sonnen | How to watch the Brazilian’s last match?

- Samsung | The first photos of the new Galaxy S24 FE revealed

- The 20 best horror films of the new generation

- The 50 funniest Google Assistant jokes

- The JBL box survives after 25 days under the mud in RS

- Antonov AN-124, the largest cargo plane, lands in Brazil

Source: Terra

Rose James is a Gossipify movie and series reviewer known for her in-depth analysis and unique perspective on the latest releases. With a background in film studies, she provides engaging and informative reviews, and keeps readers up to date with industry trends and emerging talents.