The chromium, cobalt and nickel compound becomes even more resistant when used at low temperatures

Researchers at the University of California at Berkeley, in collaboration with the Oak Ridge National Laboratory, both in the United States, have developed a new metal alloy that can be considered the strongest material ever produced on Earth.

- The carbon material manages to be lighter and stronger than Kevlar

- The material made from cellulose is harder than bone and as hard as aluminum

According to scientists, this compound composed of chromium, cobalt and nickel is extremely hard and not very prone to fracture. In particular, these properties increase considerably when the material is used at low temperatures.

“Strength, ductility and toughness are three properties that determine the durability of a material. Strength describes resistance to deformation, while ductility demonstrates how malleable a compound is,” explains mechanical engineer Robert Richie, co-author of the study.

high entropy alloys

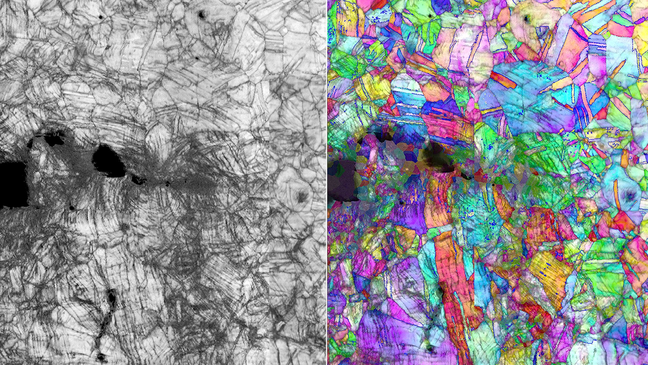

So-called high entropy alloys (HEA) contain elements mixed in equal proportions. One of these alloys in particular, composed of chromium, manganese, iron, cobalt and nickel, has strength and ductility that increase at the temperature of liquid nitrogen, without compromising its toughness.

The derivative of this alloy, consisting only of chromium, cobalt and nickel, showed even more impressive properties. By subjecting the material to the temperature of helium gas (-253°C), they achieved a constant toughness of over 500 megapascals.

“In the same proportions, the toughness of aluminum structure in passenger aircraft is about 35, and that of some of the best steel on the market hardly exceeds 100 megapascals. So getting anything over 500 is a tremendous number,” adds Richie .

new materials

Now that the researchers have managed to understand how this new metal alloy works, the idea is to design new materials that can go even further. According to them, these compounds would be ideal for applications in extreme environments, such as deep space.

Before that, scientists plan to find a way to make these alloys with cheaper and more abundant elements in nature. The global shortage of cobalt and nickel, for example, prevents the industrial-scale production of mixtures containing these metals.

“When you’re flying in an airplane, it’s not pleasant knowing that what’s responsible for your safety at 40,000 feet is an alloy that was developed months ago. That’s why structural materials can take many years, even decades, to develop to use in the real world,” concludes Professor Robert Richie.

Source: Berkeley laboratory

Trending on Canaltech:

- Scientist imagines what dinosaurs would have been like if they hadn’t gone extinct

- Kinesthesia, our sixth sense, is being revealed by scientists

- Did Motorola finally wake up with the new Edge 30?

- Surprises of the year | Few interesting mobiles; smart TVs stand out

- JBL Partybox 710 Review | Very powerful, but it’s nicheda

- Why do some toilets have horseshoe seats?

🇧🇷The best content in your email for free. Choose your favorite Terra newsletter. Click here!

Source: Terra

Camila Luna is a writer at Gossipify, where she covers the latest movies and television series. With a passion for all things entertainment, Camila brings her unique perspective to her writing and offers readers an inside look at the industry. Camila is a graduate from the University of California, Los Angeles (UCLA) with a degree in English and is also a avid movie watcher.