The dry toilet can be a viable solution for basic sanitation

when the designer Archie Read did an internship at a sanitation company, was inspired by the attention to supply dry toilets for Madagascar cities and portable toilets for high-end events.

The design student then carried out research on cities with precarious sanitation conditions, and this became his starting point for moving forward with a project that addressed the sanitation crisis: the Sandi, sustainable bathroom that uses sand.

Read elaborate on his brief for designing and prototyping a worthy waterless sanitation solution for poor countries, keeping Sub-Saharan rural Africa as his goal.

Their dry toilet solution was based on the United Nations Sustainable Development Goal for toilets and should be able to handle the droppings and urine of a family of up to seven adults for two or three days.

Most importantly, it had to be affordable enough to manufacture and purchase. From these ideas Read started with his prototype and completed it with the mechanisms of the dry toilet.

How does it work

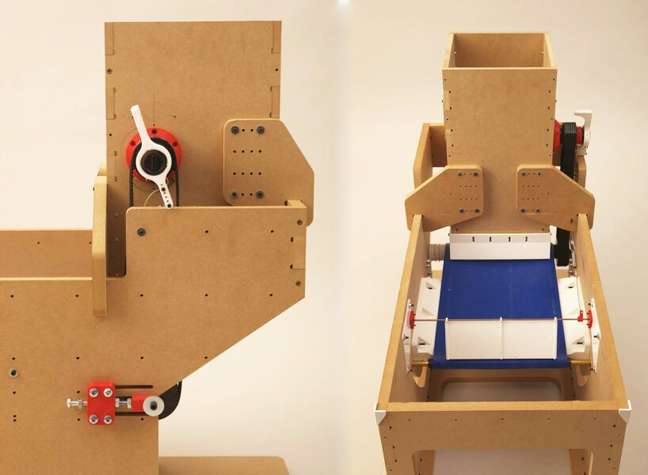

To make it work, Read installed a mechanical unloading system that uses a conveyor belt. The user fills the compartment with sand and pushes a lever to allow the sand to enter the vessel.

Once the toilet is filled with sand, the user is freed, so they can rinse their own excrement using the same lever and wait for the sand to push the dirt into the hatch that passes into the lower bin.

Read also placed a divider to separate feces from urine. This system helps separate the liquid from the solid and allows the user to treat the stool as fertilizer.

Read’s extensive testing was successful, but it revealed that one thing still needs some tweaking.

“The hatch door did not open fully and therefore residues remained. This appears to be caused by the weight of the spring not allowing it to close completely,” he writes.

Methodology

The designer has adopted the design methodology called Total Design, which covers six fundamental elements such as user needs and problems, product design specifications, conceptual design, design details, production processes and part of the post-production sales.

The method covered Read’s basics before he worked on running his cabinet. For the toilet design, he focused on the seat and lid, body, flush mechanism and containers.

Moving on, Read can catch a glimpse of Sandi, the waterless toilet, which sells for $ 72 a unit with no operating costs, as the toilet requires no construction or excavation work, just a minimal setup.

The item simply needs to be grounded, filled with rinse material and is ready to use. Sandi can also store a minimum of 20 liters of solid waste and 30 liters of liquid waste. “A seven-person house should empty it once every ten days,” Read writes.

On the other hand, Read shares that one of the biggest problems today is the cost of producing his idea, which is four times what it should be.

He plans to partner with large organizations to fund his sanitation project and with engineers and designers to perform more comprehensive testing, service and assembly processes to ensure product quality and feasibility.

* Through Designboom

Source: Terra

Benjamin Smith is a fashion journalist and author at Gossipify, known for his coverage of the latest fashion trends and industry insights. He writes about clothing, shoes, accessories, and runway shows, providing in-depth analysis and unique perspectives. He’s respected for his ability to spot emerging designers and trends, and for providing practical fashion advice to readers.

![Everything for pre -light: Victoria Solen is bent … which is waiting for you on Tuesday, August 12, August 12, 2025 in 42 episodes [SPOILERS] Everything for pre -light: Victoria Solen is bent … which is waiting for you on Tuesday, August 12, August 12, 2025 in 42 episodes [SPOILERS]](https://fr.web.img3.acsta.net/img/94/98/9498e97473cd445af2e7f350b91d357e.jpg)